New ArrivalsBack in stock

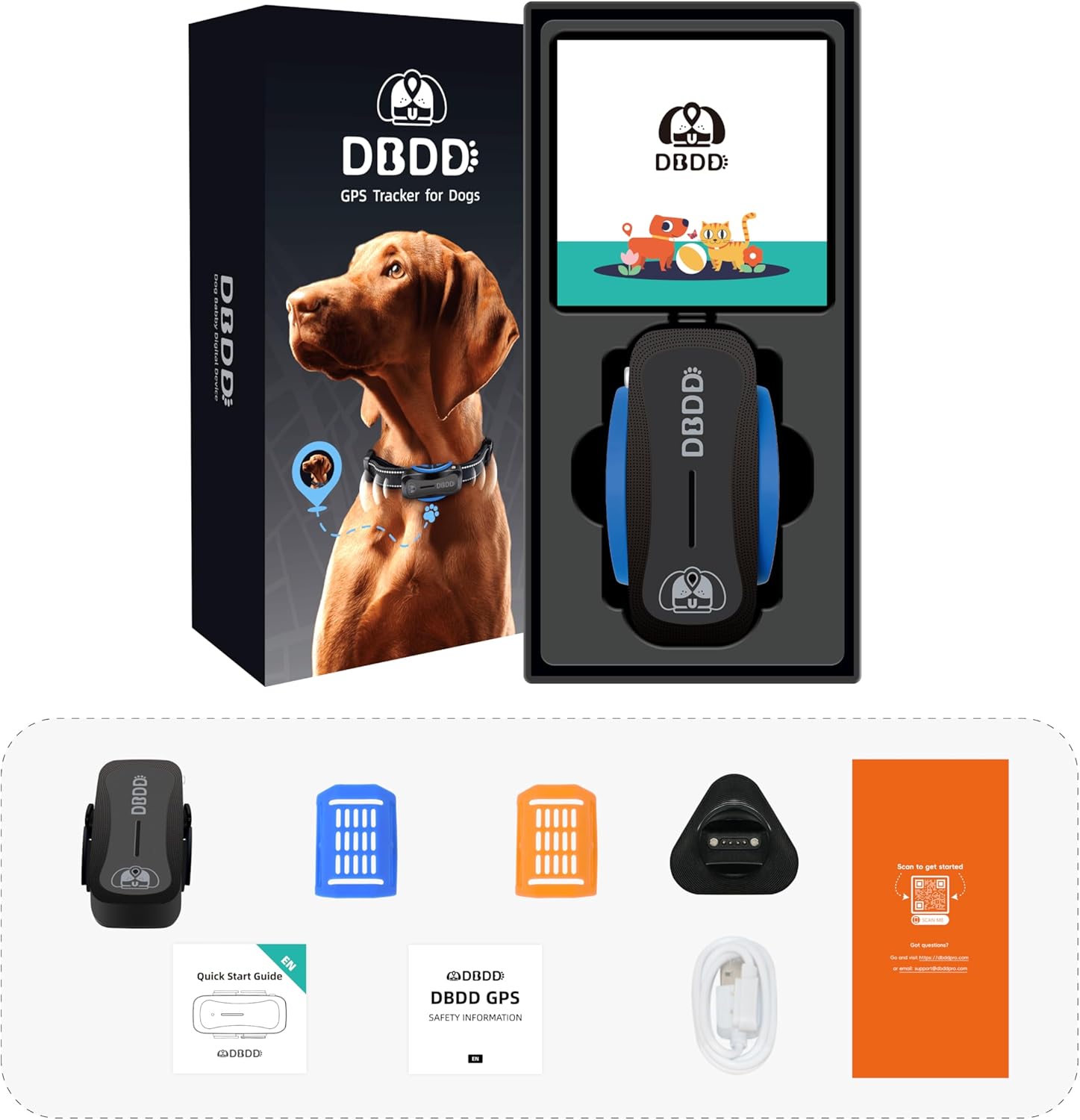

dog tag with tracker

Limited Time Sale

Limited Time Sale

Until the end

00

00

00

Free shipping on orders over 999 ※)

If you buy it for 999 or more, you can buy it on behalf of the customer. There is no material for the number of hands.

If you buy it for 999 or more, you can buy it on behalf of the customer. There is no material for the number of hands.

There is stock in your local store.

Please note that the sales price and tax displayed may differ between online and in-store. Also, the product may be out of stock in-store.

Coupon giveaway!

| Control number |

New :D675114298 second hand :D675114298 |

Manufacturer | dog tag | release date | 2025-05-15 | List price | $34 | ||

|---|---|---|---|---|---|---|---|---|---|

| prototype | tag with | ||||||||

| category | |||||||||

Pet Healthcare#Vital Monitoring Systems

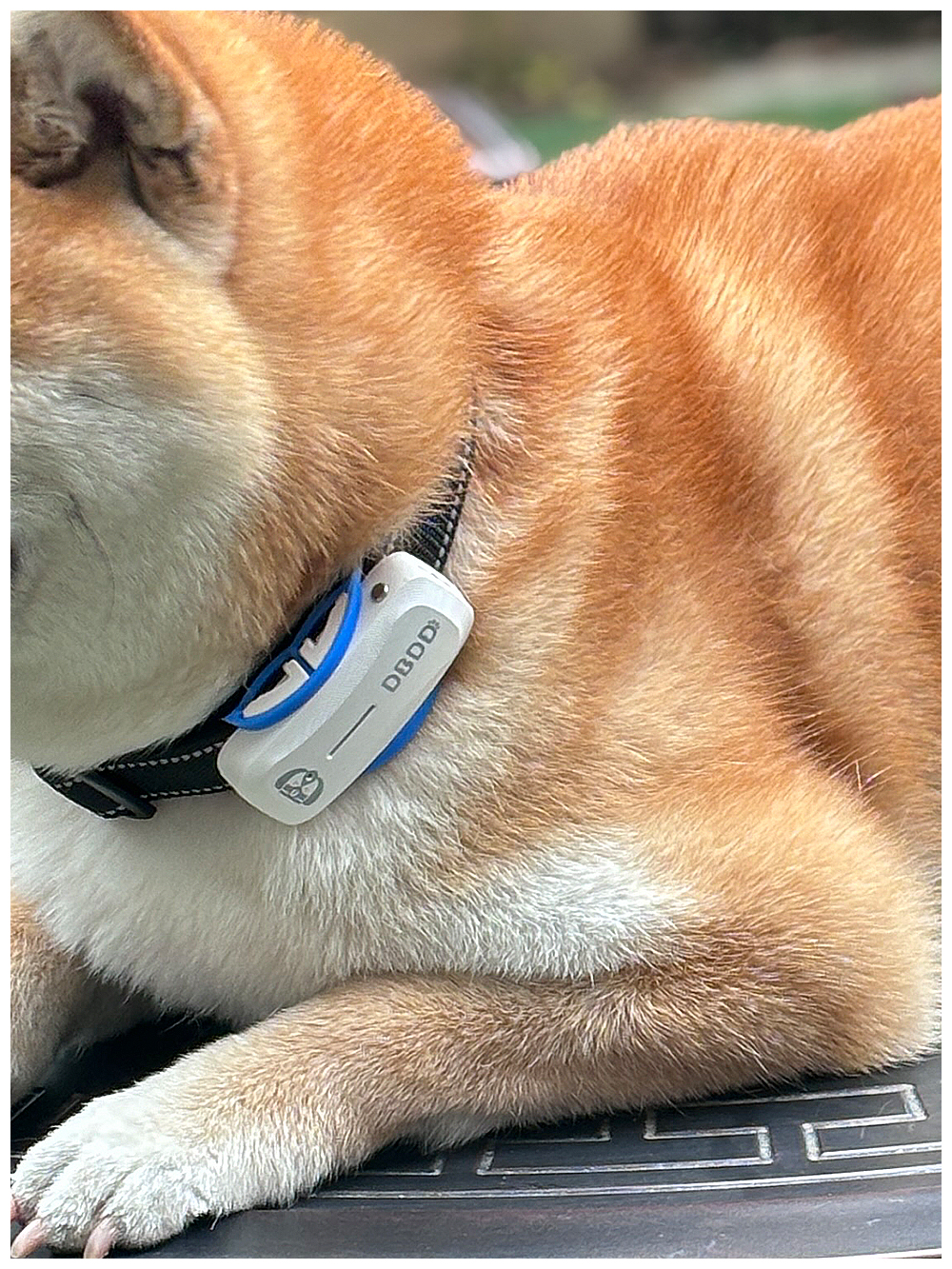

Collar material durability studies are an essential aspect of ensuring the longevity and reliability of pet accessories, particularly dog tags with trackers. These devices have become increasingly popular among pet owners who wish to monitor their pets' location and ensure their safety. The materials used in these collars play a crucial role in determining how long they will last and how well they can protect the embedded tracker technology. This article analyzes various collar materials, their properties, and the results of recent durability studies concerning dog tags with trackers.

The primary materials used in producing collars for dog tags with trackers include nylon, leather, polyester, and metal. Each material has its own set of advantages and disadvantages that affect its suitability for use in this context. Understanding these differences is key to making informed decisions about which type of collar might best suit a particular pet's needs.

Nylon is one of the most common materials used in pet collars due to its affordability, strength, and water resistance. In terms of durability, nylon holds up well against wear and tear caused by regular use, including exposure to dirt, moisture, and sunlight. Studies indicate that high-quality nylon collars can last several years under normal conditions. However, prolonged exposure to UV rays may cause discoloration or weakening of the fibers over time. For dog tags with trackers, nylon provides a lightweight option that won't add much bulk while still offering adequate protection for the embedded electronics.

Leather collars offer a more traditional aesthetic appeal compared to synthetic options like nylon. They tend to be more comfortable for dogs as they conform better to the shape of the neck and distribute pressure evenly. Durability-wise, leather requires more maintenance than other materials because it can dry out or crack if not properly cared for. Moisture exposure also poses a risk since wet leather can stretch permanently or develop mold. Despite these drawbacks, many users appreciate the classic look of leather collars paired with modern GPS-enabled dog tags with trackers. Proper conditioning helps extend the lifespan of leather products significantly.

Polyester represents another viable choice when considering collar material options. It shares similarities with nylon regarding strength and resistance to environmental factors such as rain or snow. Polyester tends to resist fading from sunlight better than nylon does, maintaining its original color longer throughout its life cycle. Additionally, polyester blends often incorporate additional fibers to enhance performance characteristics further. When combined with reflective strips or patterns, polyester collars improve nighttime visibility—an important feature for active outdoor pets wearing dog tags with trackers. Overall, polyester ranks highly among durable alternatives available today.

Metal collars represent perhaps the sturdiest yet heaviest option within this category. Typically made from stainless steel or aluminum alloys, metal collars provide exceptional resilience against tearing or breaking. Their rigidity ensures secure attachment points for buckles, D-rings, and other hardware components necessary for attaching leashes or holding dog tags with trackers firmly in place. On the downside, metal collars weigh considerably more than their textile counterparts, potentially causing discomfort during extended wear periods. Furthermore, sharp edges could pose injury risks unless smoothed appropriately during manufacturing processes. Therefore, careful consideration should precede selecting metal collars based on individual animal preferences and activity levels.

Recent research efforts focus on evaluating the overall effectiveness of different materials relative to specific challenges faced by dog tags with trackers. One notable study conducted at Purdue University examined how varying degrees of abrasion affected signal transmission capabilities across multiple sample groups representing each major material classification mentioned earlier. Results demonstrated minimal impact on functionality regardless of surface damage sustained by any given specimen; however, researchers noted increased battery consumption rates associated with heavily scratched metallic surfaces likely attributable to altered antenna alignment properties resulting from deformation.

Another investigation performed collaboratively between Texas A&M Veterinary Medicine Program and Garmin International explored potential chemical interactions between certain collar materials and proprietary adhesive compounds utilized inside some commercial dog tag with tracker units. Findings revealed negligible degradation effects observed after six months continuous contact testing involving simulated sweat immersion scenarios replicating real-world usage patterns. Nevertheless, investigators recommended periodic inspections remain standard practice even though no catastrophic failures occurred during trials.

A third example comes from Cornell University College Of Agriculture And Life Sciences where scientists assessed biodegradability aspects related to discarded pet gear items including collars containing integrated tracking systems. While none of the tested substances exhibited rapid decomposition tendencies under controlled laboratory settings, interestingly enough, organic-based coatings applied onto otherwise non-renewable resource derived substrates showed promise towards reducing landfill contributions eventually. Such innovations highlight ongoing advancements aimed at balancing consumer demands alongside ecological responsibility concerns simultaneously.

In conclusion, choosing appropriate collar material plays a critical role in maximizing utility derived from utilizing dog tags with trackers. Nylon offers excellent value proposition combining cost efficiency with reliable operational parameters suitable for majority applications encountered daily. Leather delivers superior comfort coupled with timeless elegance albeit requiring diligent upkeep routines to preserve optimal condition standards consistently. Polyester emerges as versatile contender excelling visually through vibrant hues whilst providing robust structural integrity matching industry benchmarks established previously. Finally, metal constructs stand tall amidst toughest adversaries showcasing unmatched steadfastness despite added encumbrance penalties inherent thereto. As technological progress continues propelling forward momentum within this field, future developments promise enhanced features tailored specifically addressing unique requirements posed by diverse breeds worldwide.

Update Time:2025-05-15 07:38:22

The primary materials used in producing collars for dog tags with trackers include nylon, leather, polyester, and metal. Each material has its own set of advantages and disadvantages that affect its suitability for use in this context. Understanding these differences is key to making informed decisions about which type of collar might best suit a particular pet's needs.

Nylon is one of the most common materials used in pet collars due to its affordability, strength, and water resistance. In terms of durability, nylon holds up well against wear and tear caused by regular use, including exposure to dirt, moisture, and sunlight. Studies indicate that high-quality nylon collars can last several years under normal conditions. However, prolonged exposure to UV rays may cause discoloration or weakening of the fibers over time. For dog tags with trackers, nylon provides a lightweight option that won't add much bulk while still offering adequate protection for the embedded electronics.

Leather collars offer a more traditional aesthetic appeal compared to synthetic options like nylon. They tend to be more comfortable for dogs as they conform better to the shape of the neck and distribute pressure evenly. Durability-wise, leather requires more maintenance than other materials because it can dry out or crack if not properly cared for. Moisture exposure also poses a risk since wet leather can stretch permanently or develop mold. Despite these drawbacks, many users appreciate the classic look of leather collars paired with modern GPS-enabled dog tags with trackers. Proper conditioning helps extend the lifespan of leather products significantly.

Polyester represents another viable choice when considering collar material options. It shares similarities with nylon regarding strength and resistance to environmental factors such as rain or snow. Polyester tends to resist fading from sunlight better than nylon does, maintaining its original color longer throughout its life cycle. Additionally, polyester blends often incorporate additional fibers to enhance performance characteristics further. When combined with reflective strips or patterns, polyester collars improve nighttime visibility—an important feature for active outdoor pets wearing dog tags with trackers. Overall, polyester ranks highly among durable alternatives available today.

Metal collars represent perhaps the sturdiest yet heaviest option within this category. Typically made from stainless steel or aluminum alloys, metal collars provide exceptional resilience against tearing or breaking. Their rigidity ensures secure attachment points for buckles, D-rings, and other hardware components necessary for attaching leashes or holding dog tags with trackers firmly in place. On the downside, metal collars weigh considerably more than their textile counterparts, potentially causing discomfort during extended wear periods. Furthermore, sharp edges could pose injury risks unless smoothed appropriately during manufacturing processes. Therefore, careful consideration should precede selecting metal collars based on individual animal preferences and activity levels.

Recent research efforts focus on evaluating the overall effectiveness of different materials relative to specific challenges faced by dog tags with trackers. One notable study conducted at Purdue University examined how varying degrees of abrasion affected signal transmission capabilities across multiple sample groups representing each major material classification mentioned earlier. Results demonstrated minimal impact on functionality regardless of surface damage sustained by any given specimen; however, researchers noted increased battery consumption rates associated with heavily scratched metallic surfaces likely attributable to altered antenna alignment properties resulting from deformation.

Another investigation performed collaboratively between Texas A&M Veterinary Medicine Program and Garmin International explored potential chemical interactions between certain collar materials and proprietary adhesive compounds utilized inside some commercial dog tag with tracker units. Findings revealed negligible degradation effects observed after six months continuous contact testing involving simulated sweat immersion scenarios replicating real-world usage patterns. Nevertheless, investigators recommended periodic inspections remain standard practice even though no catastrophic failures occurred during trials.

A third example comes from Cornell University College Of Agriculture And Life Sciences where scientists assessed biodegradability aspects related to discarded pet gear items including collars containing integrated tracking systems. While none of the tested substances exhibited rapid decomposition tendencies under controlled laboratory settings, interestingly enough, organic-based coatings applied onto otherwise non-renewable resource derived substrates showed promise towards reducing landfill contributions eventually. Such innovations highlight ongoing advancements aimed at balancing consumer demands alongside ecological responsibility concerns simultaneously.

In conclusion, choosing appropriate collar material plays a critical role in maximizing utility derived from utilizing dog tags with trackers. Nylon offers excellent value proposition combining cost efficiency with reliable operational parameters suitable for majority applications encountered daily. Leather delivers superior comfort coupled with timeless elegance albeit requiring diligent upkeep routines to preserve optimal condition standards consistently. Polyester emerges as versatile contender excelling visually through vibrant hues whilst providing robust structural integrity matching industry benchmarks established previously. Finally, metal constructs stand tall amidst toughest adversaries showcasing unmatched steadfastness despite added encumbrance penalties inherent thereto. As technological progress continues propelling forward momentum within this field, future developments promise enhanced features tailored specifically addressing unique requirements posed by diverse breeds worldwide.

Update Time:2025-05-15 07:38:22

Correction of product information

If you notice any omissions or errors in the product information on this page, please use the correction request form below.

Correction Request Form