New ArrivalsBack in stock

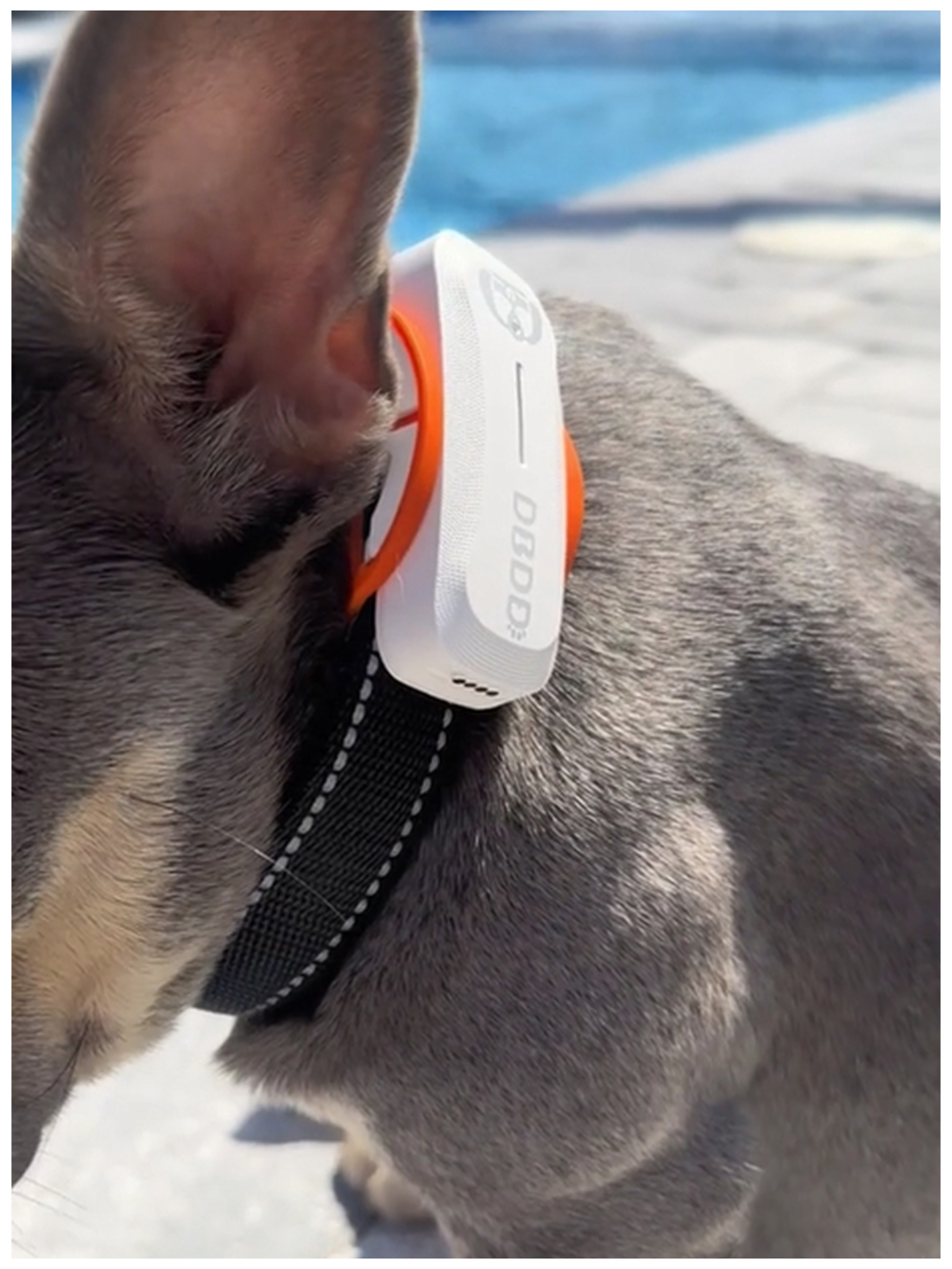

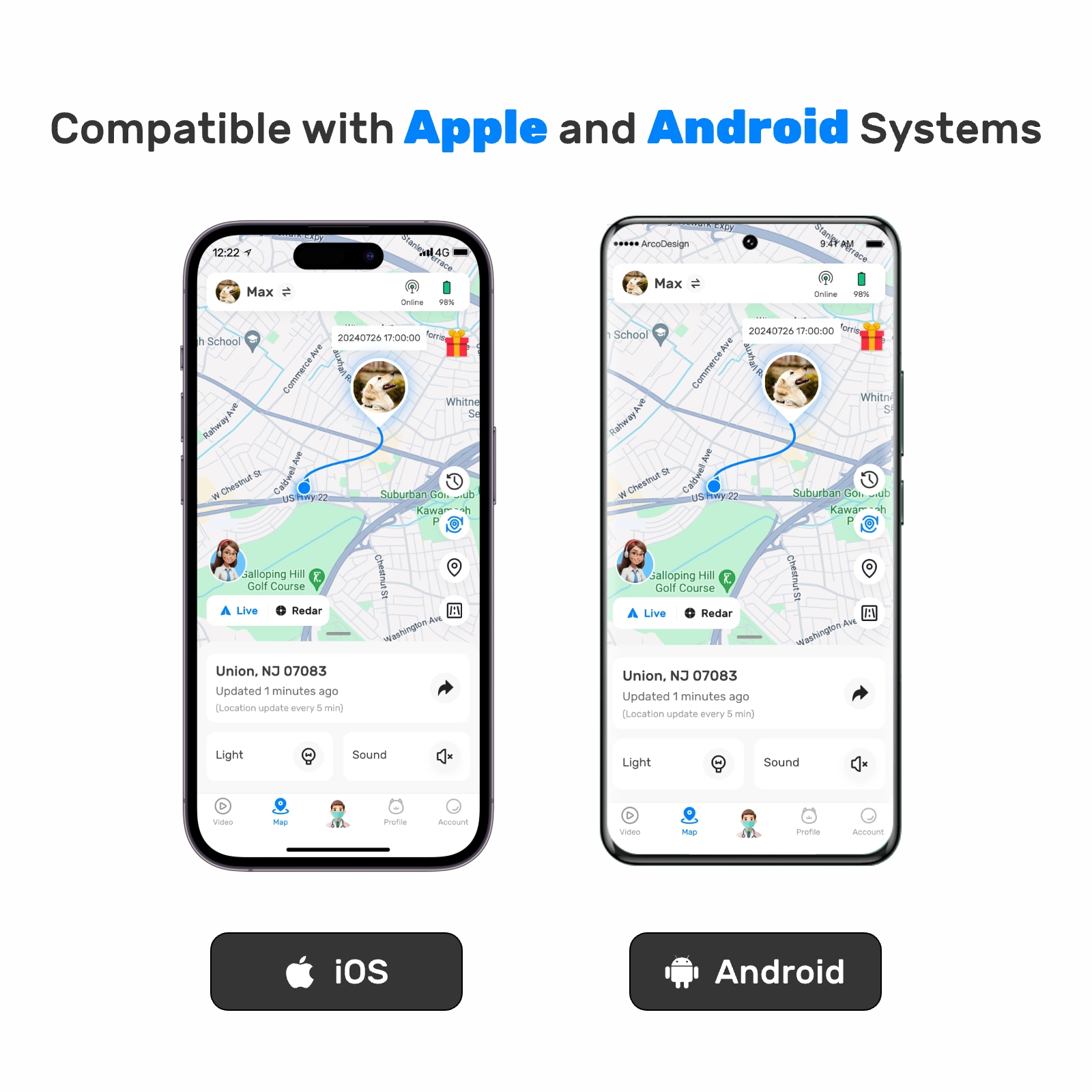

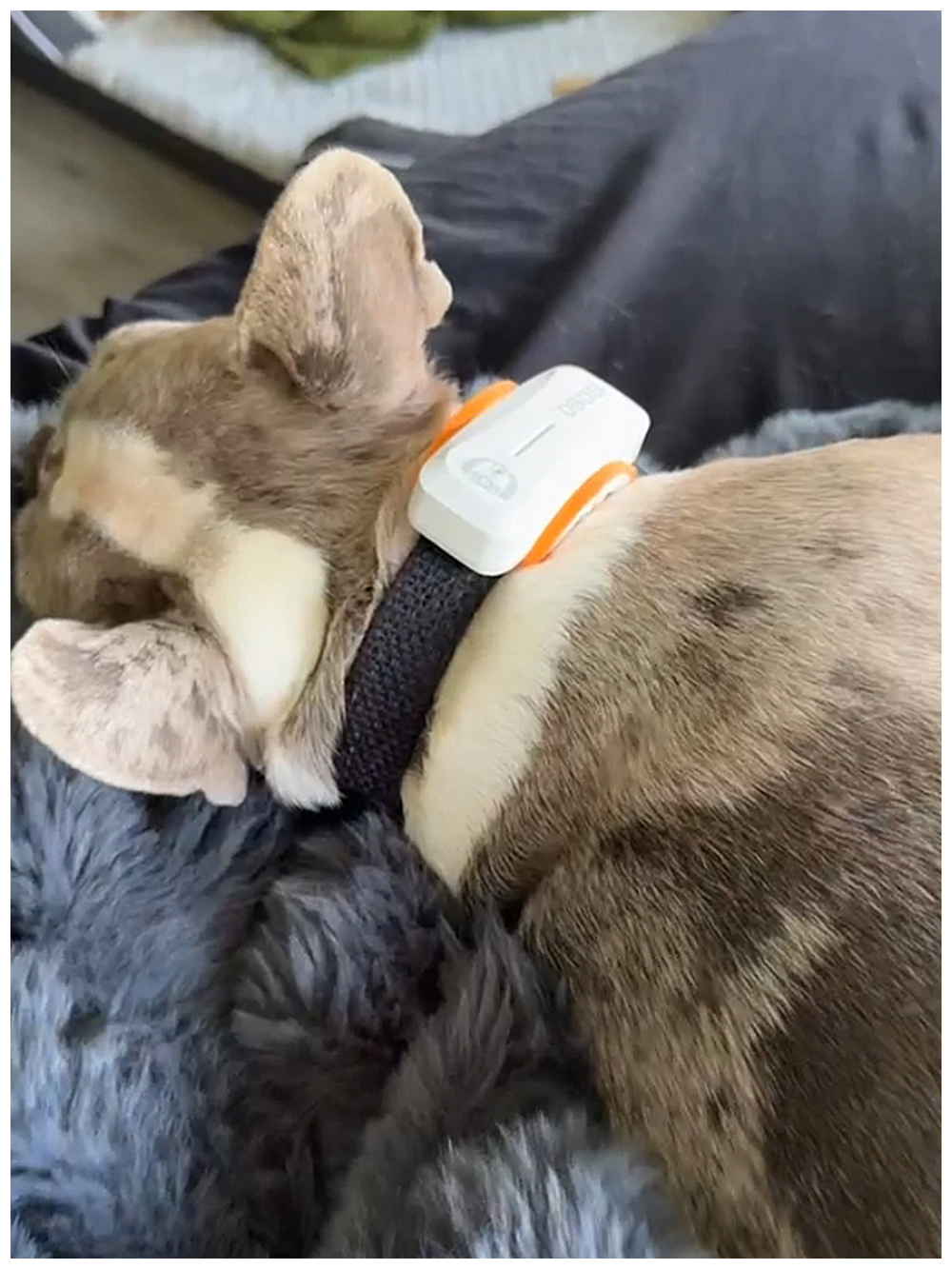

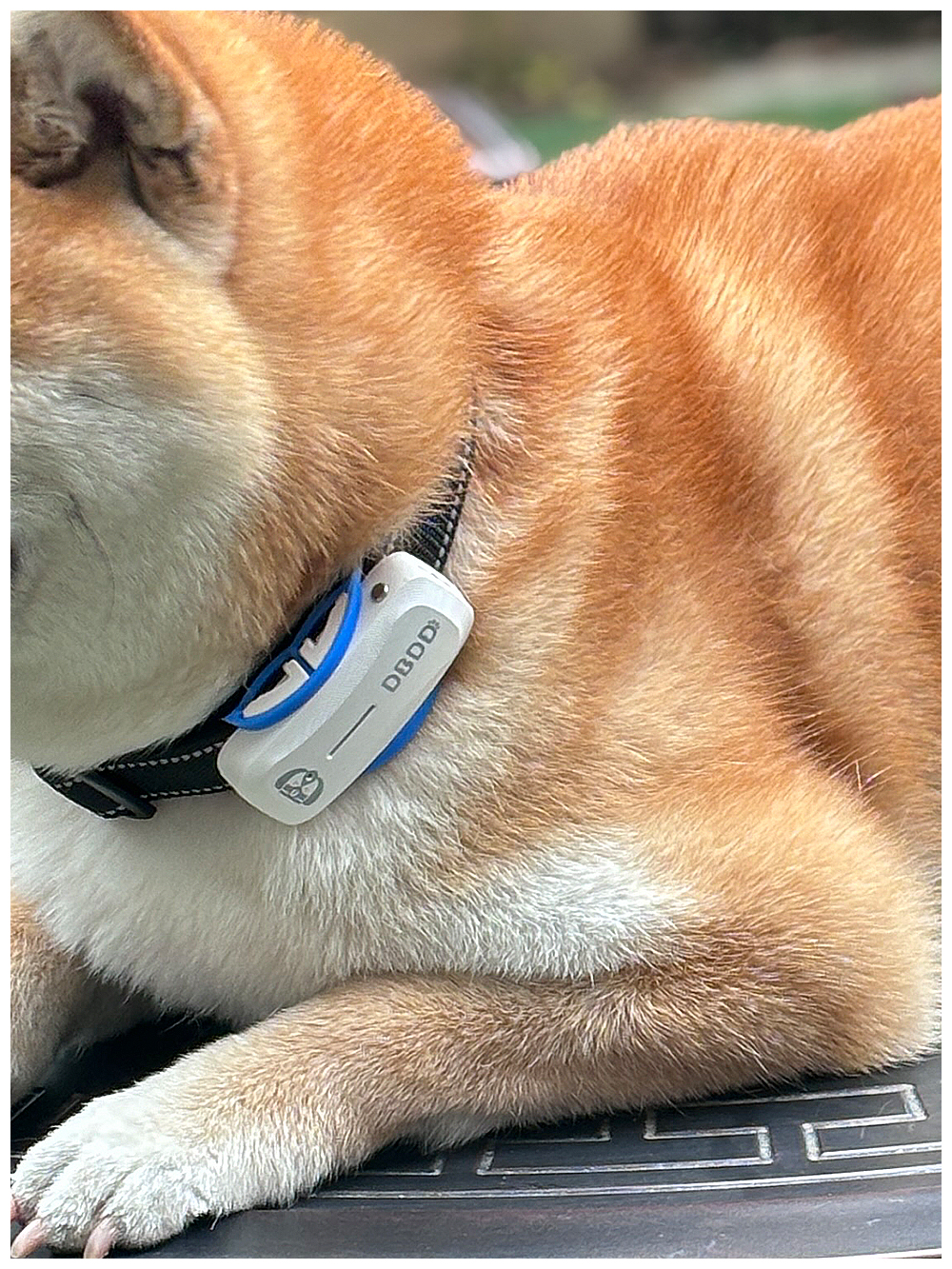

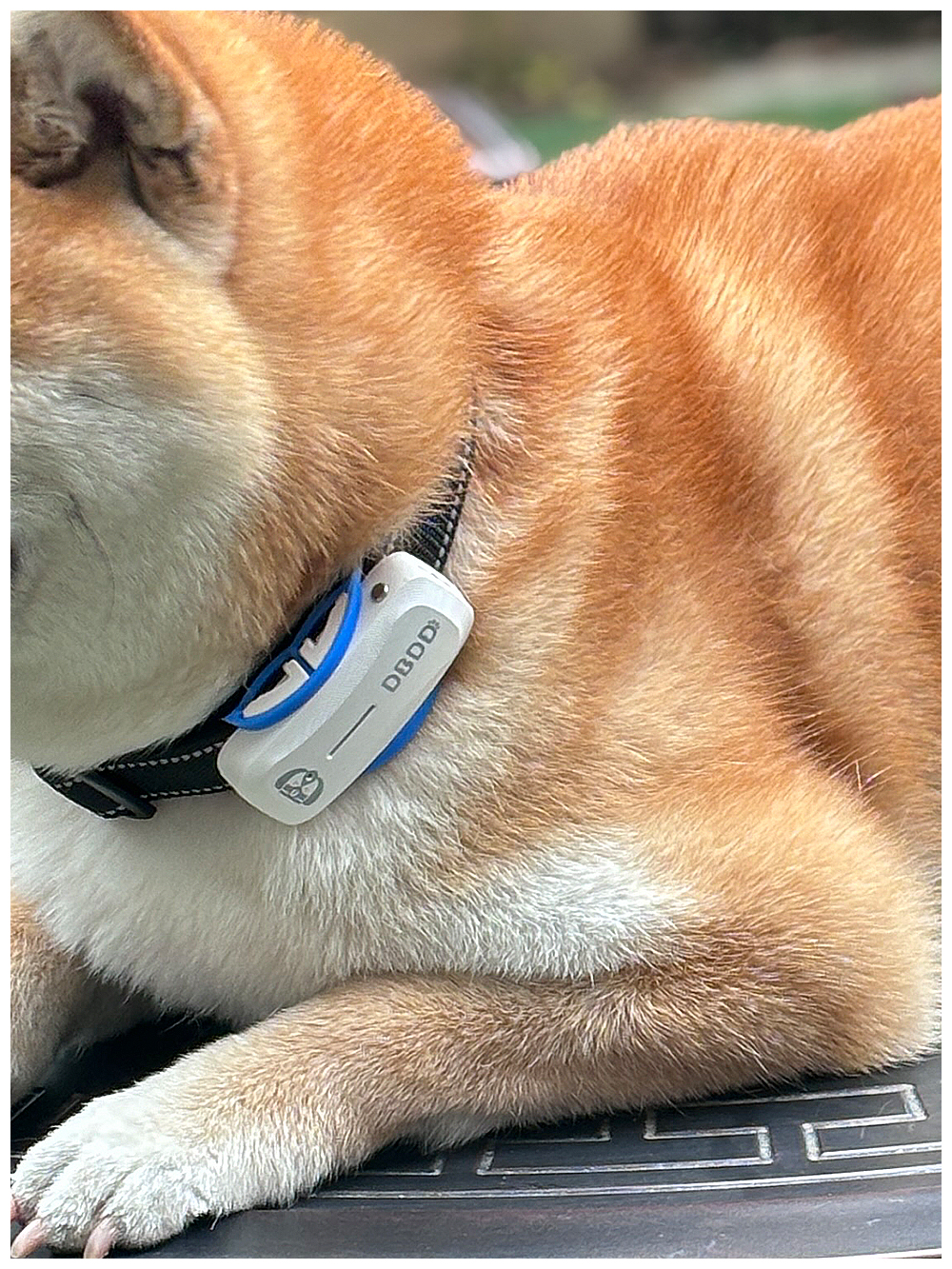

tiny tracker with gps

Limited Time Sale

Limited Time Sale

Until the end

00

00

00

Free shipping on orders over 999 ※)

If you buy it for 999 or more, you can buy it on behalf of the customer. There is no material for the number of hands.

If you buy it for 999 or more, you can buy it on behalf of the customer. There is no material for the number of hands.

There is stock in your local store.

Please note that the sales price and tax displayed may differ between online and in-store. Also, the product may be out of stock in-store.

Coupon giveaway!

| Control number |

New :D583270362 second hand :D583270362 |

Manufacturer | tiny tracker | release date | 2025-05-16 | List price | $40 | ||

|---|---|---|---|---|---|---|---|---|---|

| prototype | tracker with | ||||||||

| category | |||||||||

Retail Analytics#Pet Behavior Insights

Collar material durability studies have become increasingly important as the use of tiny trackers with GPS technology expands across various industries. These devices, often used for monitoring wildlife or managing assets, require collars that can withstand harsh environmental conditions while maintaining structural integrity over time. This analysis delves into recent studies focusing on the durability of materials used in these collars, examining their effectiveness and potential limitations.

The primary goal of any collar designed to house a tiny tracker with GPS is to ensure that it remains functional and secure under varying circumstances. Researchers have explored numerous materials, each offering unique properties that cater to specific needs. Among the most commonly studied materials are nylon, leather, rubber, and advanced composites such as carbon fiber-reinforced polymers. Each material presents its own set of advantages and challenges when subjected to prolonged exposure to natural elements like sunlight, moisture, and temperature fluctuations.

Nylon has long been favored for its strength-to-weight ratio and resistance to abrasion. Studies indicate that nylon-based collars offer excellent durability, particularly in dry environments where UV degradation poses minimal risk. However, prolonged exposure to water can lead to weakening of the fibers, reducing the collar's lifespan. To mitigate this issue, manufacturers often incorporate coatings or treatments that enhance nylon's resistance to moisture. Despite these efforts, researchers caution that even treated nylon may not be suitable for aquatic species tracking due to its limited hydrolytic stability.

Leather, another traditional choice, provides comfort and flexibility but suffers from significant drawbacks related to durability. While it offers an aesthetic appeal unmatched by synthetic alternatives, leather deteriorates rapidly when exposed to water and sunlight. Consequently, its application in tiny tracker with GPS systems is largely restricted to indoor or controlled-environment scenarios. Efforts to improve leather's resilience through chemical treatments have shown promise, yet they come at the cost of increased weight and reduced breathability—factors critical for animal welfare considerations.

Rubber emerges as a viable option for applications requiring high elasticity and shock absorption. Its ability to stretch without breaking makes rubber ideal for collars intended for active animals or those prone to vigorous movement. Durability studies reveal that rubber collars exhibit superior performance in wet conditions, resisting both water ingress and microbial growth. Nevertheless, rubber's susceptibility to ozone cracking and UV degradation necessitates careful formulation to extend its service life. Advances in vulcanization techniques and additive incorporation continue to address these vulnerabilities, making rubber an increasingly attractive material for tiny tracker with GPS deployments.

Advanced composite materials represent the cutting edge of collar design innovation. Composites such as carbon fiber-reinforced polymers combine exceptional strength with lightweight characteristics, making them well-suited for demanding applications. Research highlights their unparalleled resistance to environmental stressors, including extreme temperatures and corrosive agents. Moreover, composites allow for intricate shaping and customization, enabling precise fitment tailored to individual subjects. However, the high cost associated with producing composite collars remains a barrier to widespread adoption. Additionally, concerns regarding recyclability persist, prompting ongoing investigations into more sustainable manufacturing processes.

Beyond material selection, several external factors influence collar durability. For instance, the frequency and intensity of physical contact between the collar and surrounding objects play a crucial role in determining wear patterns. Studies conducted on wildlife tracking projects demonstrate that collars placed on animals inhabiting dense vegetation experience accelerated wear compared to those in open habitats. Similarly, abrasive surfaces encountered during burrowing activities contribute significantly to material erosion. Addressing these issues requires innovative solutions, such as incorporating protective layers or designing modular components that facilitate easy replacement of worn parts.

Another critical aspect influencing collar longevity involves attachment mechanisms. Traditional buckle-and-loop designs remain popular due to their simplicity and ease of adjustment. Yet, research underscores the importance of transitioning towards more secure fastening methods, especially for tiny tracker with GPS units intended for long-term deployment. Quick-release clips and snap-fit connectors represent promising alternatives, providing enhanced reliability while minimizing user error during installation. Furthermore, integrating electronic sensors within the collar itself enables real-time monitoring of tension levels, alerting users to potential loosening before it compromises device functionality.

In addition to mechanical considerations, electrical insulation plays a pivotal role in ensuring the proper operation of embedded GPS modules. Collar materials must effectively shield sensitive electronics from electromagnetic interference (EMI) while maintaining adequate thermal management capabilities. Studies evaluating different insulation strategies emphasize the necessity of balancing conductivity and permeability to optimize signal reception without overheating internal components. Some researchers advocate for multi-layered architectures combining conductive and dielectric layers, whereas others explore nanotechnology-based approaches to achieve superior EMI shielding efficiency.

As awareness grows concerning the ecological impact of discarded collars, sustainability has become a focal point in material development efforts. Scientists are actively investigating biodegradable options capable of decomposing naturally after completing their useful lifecycle. Polylactic acid (PLA)-based composites derived from renewable resources show particular promise in this regard, exhibiting comparable mechanical properties to conventional plastics while reducing reliance on fossil fuels. Although challenges remain regarding scalability and cost-effectiveness, continued advancements in bioengineering hold great potential for transforming the industry landscape.

Looking ahead, future research directions should prioritize interdisciplinary collaboration bridging materials science, engineering, and environmental biology. By leveraging insights gained from diverse fields, developers can create next-generation collars that not only meet stringent durability requirements but also align with ethical standards governing animal care and conservation practices. Key areas warranting further exploration include adaptive materials responsive to environmental stimuli, self-healing technologies capable of autonomously repairing minor damages, and smart textiles integrating multifunctional features beyond mere GPS tracking.

In conclusion, collar material durability represents a complex yet fascinating domain ripe for discovery and innovation. As demonstrated through extensive studies, no single material universally excels across all possible use cases involving tiny tracker with GPS devices. Instead, optimal choices depend heavily on application-specific demands and operational contexts. By staying abreast of emerging trends and technological breakthroughs, stakeholders can make informed decisions leading to improved product performance and extended service lives. Ultimately, fostering sustained dialogue among researchers, manufacturers, and end-users will drive progress toward creating truly resilient and eco-friendly solutions tailored to meet tomorrow's challenges today.

Update Time:2025-05-16 05:49:29

The primary goal of any collar designed to house a tiny tracker with GPS is to ensure that it remains functional and secure under varying circumstances. Researchers have explored numerous materials, each offering unique properties that cater to specific needs. Among the most commonly studied materials are nylon, leather, rubber, and advanced composites such as carbon fiber-reinforced polymers. Each material presents its own set of advantages and challenges when subjected to prolonged exposure to natural elements like sunlight, moisture, and temperature fluctuations.

Nylon has long been favored for its strength-to-weight ratio and resistance to abrasion. Studies indicate that nylon-based collars offer excellent durability, particularly in dry environments where UV degradation poses minimal risk. However, prolonged exposure to water can lead to weakening of the fibers, reducing the collar's lifespan. To mitigate this issue, manufacturers often incorporate coatings or treatments that enhance nylon's resistance to moisture. Despite these efforts, researchers caution that even treated nylon may not be suitable for aquatic species tracking due to its limited hydrolytic stability.

Leather, another traditional choice, provides comfort and flexibility but suffers from significant drawbacks related to durability. While it offers an aesthetic appeal unmatched by synthetic alternatives, leather deteriorates rapidly when exposed to water and sunlight. Consequently, its application in tiny tracker with GPS systems is largely restricted to indoor or controlled-environment scenarios. Efforts to improve leather's resilience through chemical treatments have shown promise, yet they come at the cost of increased weight and reduced breathability—factors critical for animal welfare considerations.

Rubber emerges as a viable option for applications requiring high elasticity and shock absorption. Its ability to stretch without breaking makes rubber ideal for collars intended for active animals or those prone to vigorous movement. Durability studies reveal that rubber collars exhibit superior performance in wet conditions, resisting both water ingress and microbial growth. Nevertheless, rubber's susceptibility to ozone cracking and UV degradation necessitates careful formulation to extend its service life. Advances in vulcanization techniques and additive incorporation continue to address these vulnerabilities, making rubber an increasingly attractive material for tiny tracker with GPS deployments.

Advanced composite materials represent the cutting edge of collar design innovation. Composites such as carbon fiber-reinforced polymers combine exceptional strength with lightweight characteristics, making them well-suited for demanding applications. Research highlights their unparalleled resistance to environmental stressors, including extreme temperatures and corrosive agents. Moreover, composites allow for intricate shaping and customization, enabling precise fitment tailored to individual subjects. However, the high cost associated with producing composite collars remains a barrier to widespread adoption. Additionally, concerns regarding recyclability persist, prompting ongoing investigations into more sustainable manufacturing processes.

Beyond material selection, several external factors influence collar durability. For instance, the frequency and intensity of physical contact between the collar and surrounding objects play a crucial role in determining wear patterns. Studies conducted on wildlife tracking projects demonstrate that collars placed on animals inhabiting dense vegetation experience accelerated wear compared to those in open habitats. Similarly, abrasive surfaces encountered during burrowing activities contribute significantly to material erosion. Addressing these issues requires innovative solutions, such as incorporating protective layers or designing modular components that facilitate easy replacement of worn parts.

Another critical aspect influencing collar longevity involves attachment mechanisms. Traditional buckle-and-loop designs remain popular due to their simplicity and ease of adjustment. Yet, research underscores the importance of transitioning towards more secure fastening methods, especially for tiny tracker with GPS units intended for long-term deployment. Quick-release clips and snap-fit connectors represent promising alternatives, providing enhanced reliability while minimizing user error during installation. Furthermore, integrating electronic sensors within the collar itself enables real-time monitoring of tension levels, alerting users to potential loosening before it compromises device functionality.

In addition to mechanical considerations, electrical insulation plays a pivotal role in ensuring the proper operation of embedded GPS modules. Collar materials must effectively shield sensitive electronics from electromagnetic interference (EMI) while maintaining adequate thermal management capabilities. Studies evaluating different insulation strategies emphasize the necessity of balancing conductivity and permeability to optimize signal reception without overheating internal components. Some researchers advocate for multi-layered architectures combining conductive and dielectric layers, whereas others explore nanotechnology-based approaches to achieve superior EMI shielding efficiency.

As awareness grows concerning the ecological impact of discarded collars, sustainability has become a focal point in material development efforts. Scientists are actively investigating biodegradable options capable of decomposing naturally after completing their useful lifecycle. Polylactic acid (PLA)-based composites derived from renewable resources show particular promise in this regard, exhibiting comparable mechanical properties to conventional plastics while reducing reliance on fossil fuels. Although challenges remain regarding scalability and cost-effectiveness, continued advancements in bioengineering hold great potential for transforming the industry landscape.

Looking ahead, future research directions should prioritize interdisciplinary collaboration bridging materials science, engineering, and environmental biology. By leveraging insights gained from diverse fields, developers can create next-generation collars that not only meet stringent durability requirements but also align with ethical standards governing animal care and conservation practices. Key areas warranting further exploration include adaptive materials responsive to environmental stimuli, self-healing technologies capable of autonomously repairing minor damages, and smart textiles integrating multifunctional features beyond mere GPS tracking.

In conclusion, collar material durability represents a complex yet fascinating domain ripe for discovery and innovation. As demonstrated through extensive studies, no single material universally excels across all possible use cases involving tiny tracker with GPS devices. Instead, optimal choices depend heavily on application-specific demands and operational contexts. By staying abreast of emerging trends and technological breakthroughs, stakeholders can make informed decisions leading to improved product performance and extended service lives. Ultimately, fostering sustained dialogue among researchers, manufacturers, and end-users will drive progress toward creating truly resilient and eco-friendly solutions tailored to meet tomorrow's challenges today.

Update Time:2025-05-16 05:49:29

Correction of product information

If you notice any omissions or errors in the product information on this page, please use the correction request form below.

Correction Request Form