New ArrivalsBack in stock

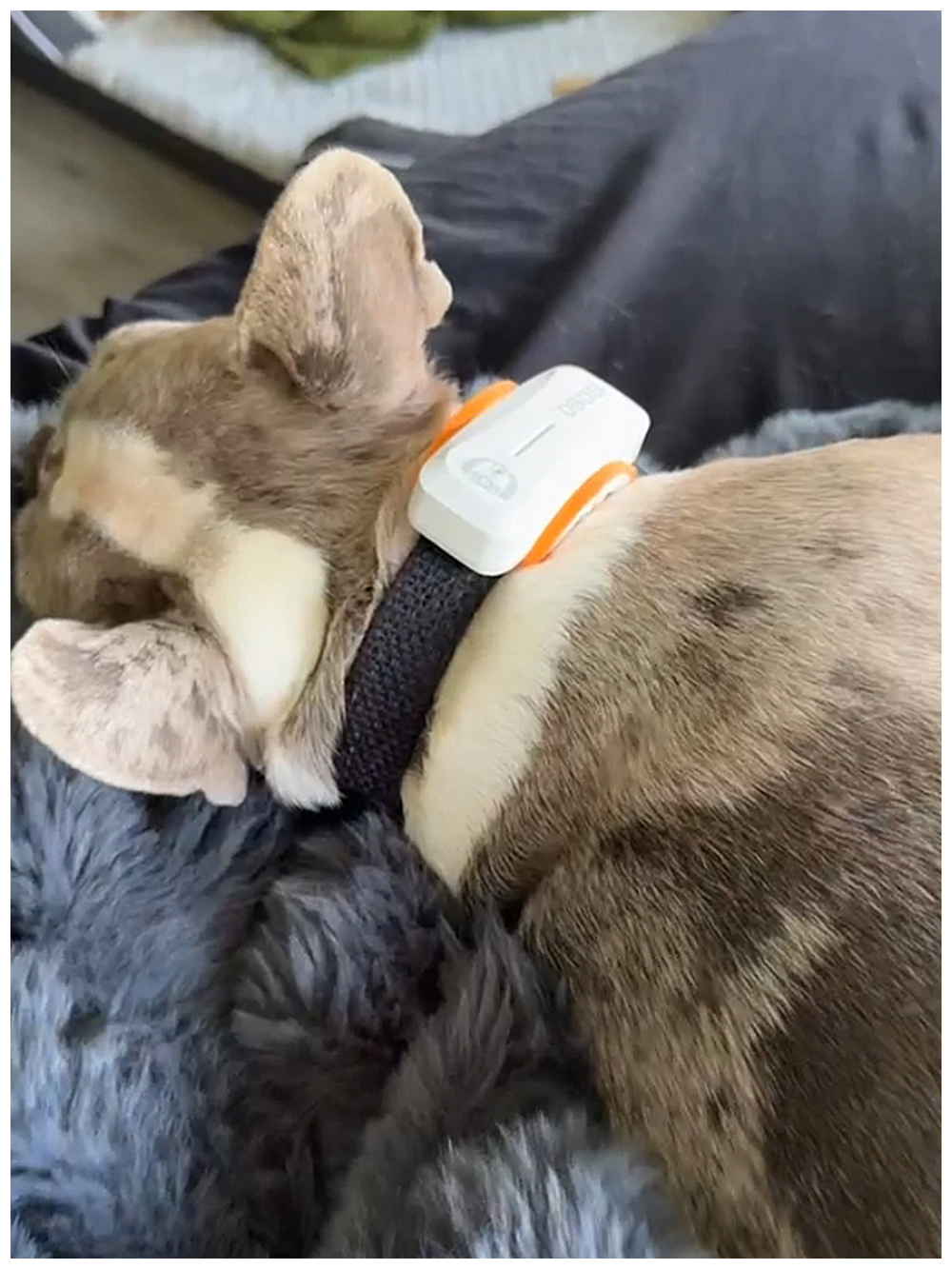

gps dog collars

Limited Time Sale

Limited Time Sale

Until the end

00

00

00

Free shipping on orders over 999 ※)

If you buy it for 999 or more, you can buy it on behalf of the customer. There is no material for the number of hands.

If you buy it for 999 or more, you can buy it on behalf of the customer. There is no material for the number of hands.

There is stock in your local store.

Please note that the sales price and tax displayed may differ between online and in-store. Also, the product may be out of stock in-store.

Coupon giveaway!

| Control number |

New :D164481258 second hand :D164481258 |

Manufacturer | gps dog | release date | 2025-05-15 | List price | $45 | ||

|---|---|---|---|---|---|---|---|---|---|

| prototype | dog collars | ||||||||

| category | |||||||||

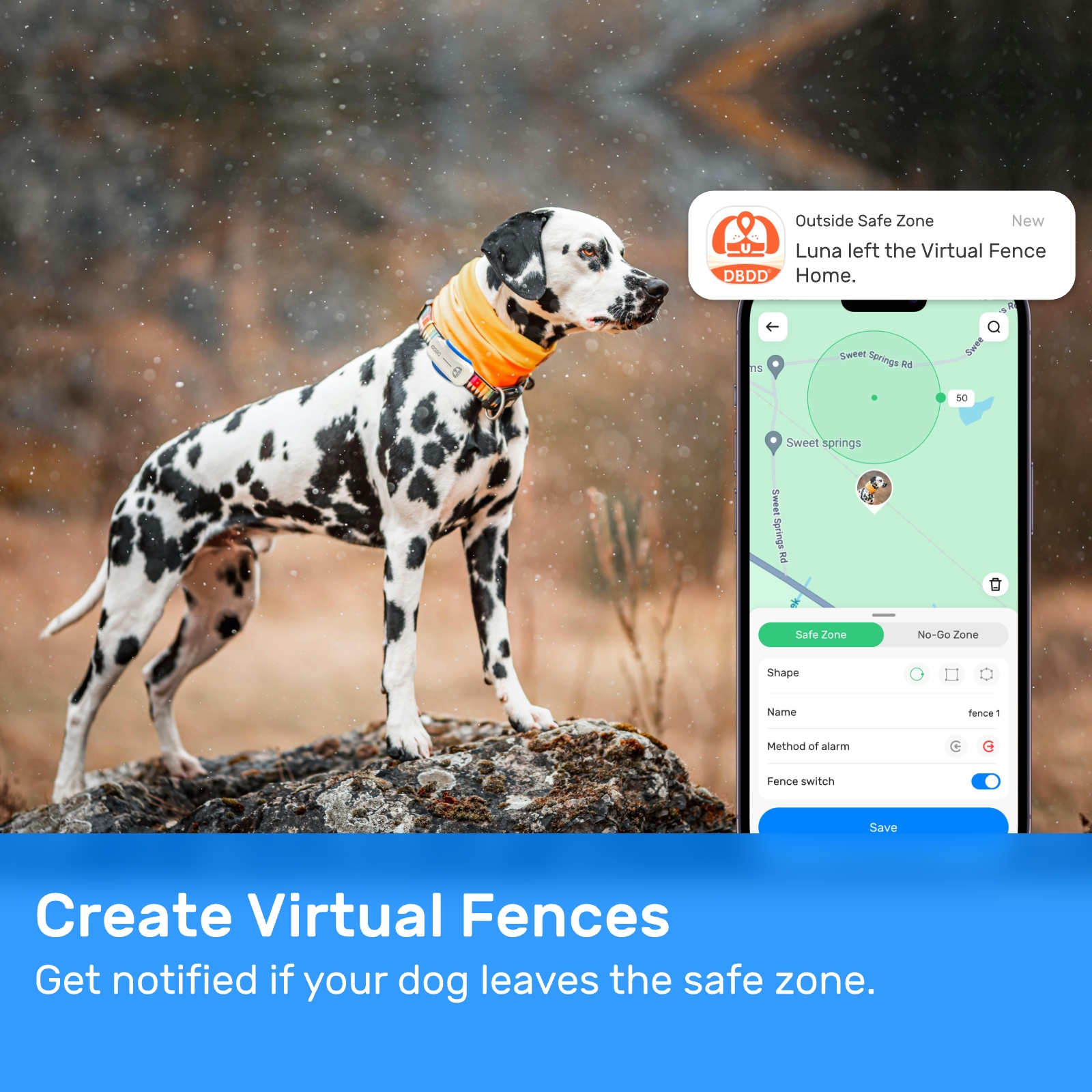

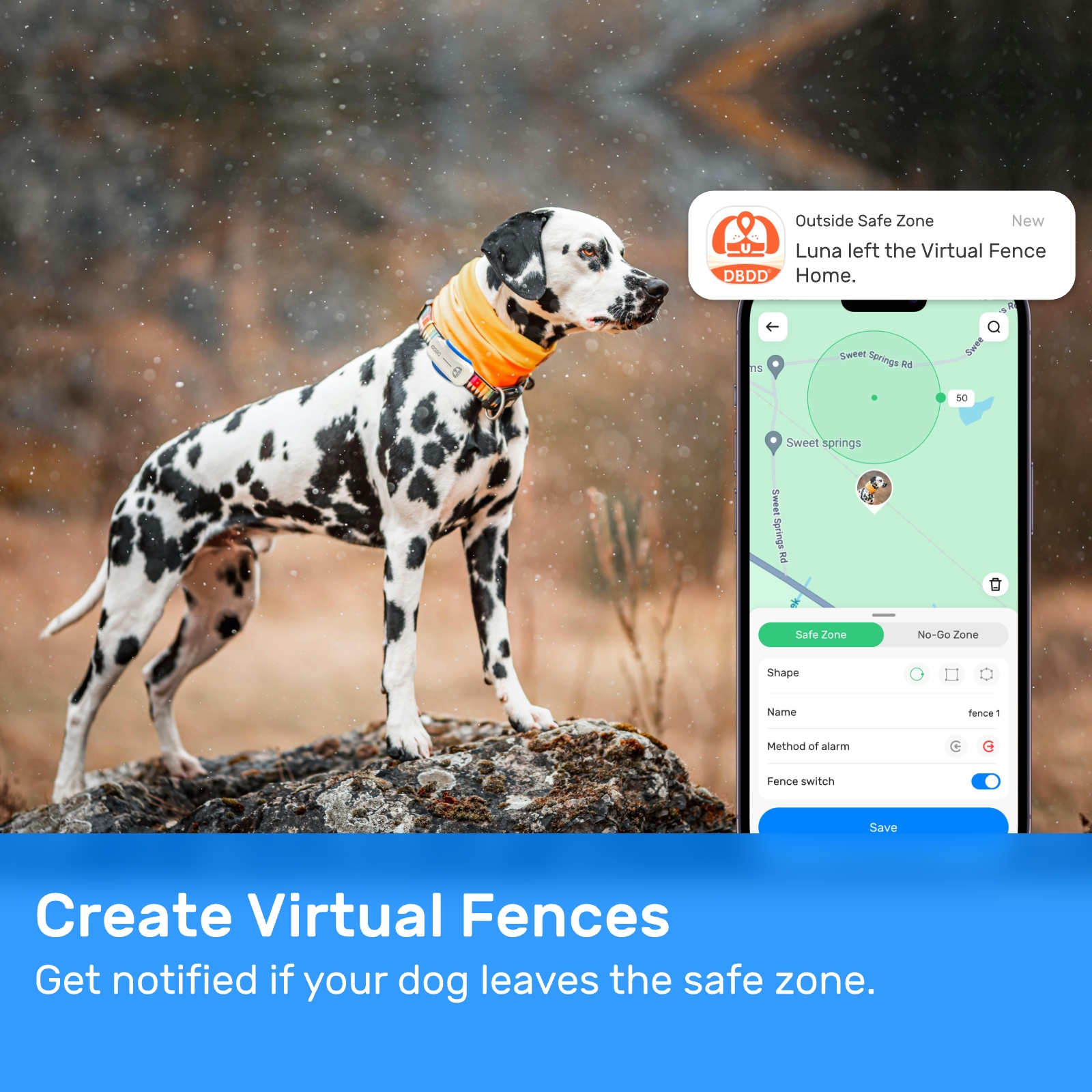

Emergency Response#Lost Pet Recovery

In the world of pet technology, GPS dog collars have emerged as a popular solution for tracking and ensuring the safety of our furry companions. These collars are designed to provide pet owners with real-time location updates, allowing them to locate their pets even if they wander off. However, as with any product that is exposed to the elements and subjected to the wear and tear of daily use, the durability of the collar material is a critical factor in determining the longevity and effectiveness of GPS dog collars. This article delves into the studies and research surrounding the durability of collar materials for GPS dog collars, examining the factors that contribute to their longevity and the advancements in material science that are improving their resilience.

**Material Science and GPS Dog Collars**

The primary materials used in the construction of GPS dog collars include plastics, rubber, and various types of synthetic fabrics. These materials are chosen for their durability, water resistance, and comfort for the pet. Studies have shown that the durability of these materials is influenced by several factors, including the type of polymer used, the manufacturing process, and the specific conditions the collar is exposed to.

**Polymer Types and Their Durability**

Polymers are large molecules composed of repeating structural units, and they are the backbone of many materials used in GPS dog collars. The most common polymers used in these collars are polyethylene (PE), polyvinyl chloride (PVC), and polyurethane (PU). Each of these polymers has its own set of properties that contribute to the overall durability of the collar.

- **Polyethylene (PE)**: Known for its flexibility and resistance to chemicals, polyethylene is a common choice for collars because it is lightweight and relatively inexpensive. However, PE has a lower resistance to UV radiation, which can lead to degradation over time when exposed to sunlight.

- **Polyvinyl Chloride (PVC)**: PVC is a versatile material that is resistant to chemicals, water, and abrasion. It is often used in the production of durable goods, but it can be less flexible and more prone to cracking under stress compared to PE.

- **Polyurethane (PU)**: PU is known for its strength, flexibility, and resistance to abrasion. It is often used in high-end GPS dog collars due to its durability and comfort for the pet. However, PU can be more expensive than other polymers and may require special manufacturing processes.

**Manufacturing Processes and Material Durability**

The manufacturing process plays a significant role in the durability of GPS dog collar materials. Techniques such as injection molding, extrusion, and thermoforming can all influence the final properties of the material. For instance, the way polymers are mixed and heated during the molding process can affect their molecular structure, which in turn can impact the collar's resistance to wear and tear.

Research has shown that additives can be incorporated into the polymers to enhance their durability. For example, UV stabilizers can be added to PE to improve its resistance to degradation from sunlight, while antioxidants can be used to prevent the breakdown of the polymer chains, thus increasing the collar's lifespan.

**Environmental Factors Affecting Durability**

GPS dog collars are exposed to a variety of environmental factors that can impact their durability, including temperature, humidity, and exposure to sunlight. Studies have shown that extreme temperatures can cause polymers to become more brittle or flexible, which can lead to cracking or deformation. High humidity can also lead to the absorption of moisture by the collar material, which can cause swelling and degradation over time.

UV radiation from the sun is a particularly harsh factor for GPS dog collars, as it can cause the polymers to break down and lose their structural integrity. This is especially true for collars that are left outdoors for extended periods or used in regions with intense sunlight.

**Advancements in Material Science**

Recent advancements in material science have led to the development of new materials and coatings that can improve the durability of GPS dog collars. For example, nanotechnology has been used to create coatings that can protect the polymers from UV radiation, reducing the rate of degradation. Additionally, the development of eco-friendly materials that are biodegradable and non-toxic is an area of active research, which could lead to more sustainable options for GPS dog collars.

**Testing and Standards for GPS Dog Collar Materials**

To ensure the durability of GPS dog collar materials, manufacturers often subject their products to rigorous testing. This can include stress tests to determine the collar's resistance to stretching and tearing, as well as exposure to simulated environmental conditions to assess how the material degrades over time.

There are also industry standards and certifications that GPS dog collars must meet to ensure their safety and durability. For example, the International Organization for Standardization (ISO) has established a series of standards for pet products, including ISO 17034, which covers the safety and performance requirements for pet containment systems, which can include GPS dog collars.

**Conclusion**

The durability of GPS dog collar materials is a complex issue that involves

Update Time:2025-05-15 13:10:12

**Material Science and GPS Dog Collars**

The primary materials used in the construction of GPS dog collars include plastics, rubber, and various types of synthetic fabrics. These materials are chosen for their durability, water resistance, and comfort for the pet. Studies have shown that the durability of these materials is influenced by several factors, including the type of polymer used, the manufacturing process, and the specific conditions the collar is exposed to.

**Polymer Types and Their Durability**

Polymers are large molecules composed of repeating structural units, and they are the backbone of many materials used in GPS dog collars. The most common polymers used in these collars are polyethylene (PE), polyvinyl chloride (PVC), and polyurethane (PU). Each of these polymers has its own set of properties that contribute to the overall durability of the collar.

- **Polyethylene (PE)**: Known for its flexibility and resistance to chemicals, polyethylene is a common choice for collars because it is lightweight and relatively inexpensive. However, PE has a lower resistance to UV radiation, which can lead to degradation over time when exposed to sunlight.

- **Polyvinyl Chloride (PVC)**: PVC is a versatile material that is resistant to chemicals, water, and abrasion. It is often used in the production of durable goods, but it can be less flexible and more prone to cracking under stress compared to PE.

- **Polyurethane (PU)**: PU is known for its strength, flexibility, and resistance to abrasion. It is often used in high-end GPS dog collars due to its durability and comfort for the pet. However, PU can be more expensive than other polymers and may require special manufacturing processes.

**Manufacturing Processes and Material Durability**

The manufacturing process plays a significant role in the durability of GPS dog collar materials. Techniques such as injection molding, extrusion, and thermoforming can all influence the final properties of the material. For instance, the way polymers are mixed and heated during the molding process can affect their molecular structure, which in turn can impact the collar's resistance to wear and tear.

Research has shown that additives can be incorporated into the polymers to enhance their durability. For example, UV stabilizers can be added to PE to improve its resistance to degradation from sunlight, while antioxidants can be used to prevent the breakdown of the polymer chains, thus increasing the collar's lifespan.

**Environmental Factors Affecting Durability**

GPS dog collars are exposed to a variety of environmental factors that can impact their durability, including temperature, humidity, and exposure to sunlight. Studies have shown that extreme temperatures can cause polymers to become more brittle or flexible, which can lead to cracking or deformation. High humidity can also lead to the absorption of moisture by the collar material, which can cause swelling and degradation over time.

UV radiation from the sun is a particularly harsh factor for GPS dog collars, as it can cause the polymers to break down and lose their structural integrity. This is especially true for collars that are left outdoors for extended periods or used in regions with intense sunlight.

**Advancements in Material Science**

Recent advancements in material science have led to the development of new materials and coatings that can improve the durability of GPS dog collars. For example, nanotechnology has been used to create coatings that can protect the polymers from UV radiation, reducing the rate of degradation. Additionally, the development of eco-friendly materials that are biodegradable and non-toxic is an area of active research, which could lead to more sustainable options for GPS dog collars.

**Testing and Standards for GPS Dog Collar Materials**

To ensure the durability of GPS dog collar materials, manufacturers often subject their products to rigorous testing. This can include stress tests to determine the collar's resistance to stretching and tearing, as well as exposure to simulated environmental conditions to assess how the material degrades over time.

There are also industry standards and certifications that GPS dog collars must meet to ensure their safety and durability. For example, the International Organization for Standardization (ISO) has established a series of standards for pet products, including ISO 17034, which covers the safety and performance requirements for pet containment systems, which can include GPS dog collars.

**Conclusion**

The durability of GPS dog collar materials is a complex issue that involves

Update Time:2025-05-15 13:10:12

Correction of product information

If you notice any omissions or errors in the product information on this page, please use the correction request form below.

Correction Request Form