New ArrivalsBack in stock

purina dog food

Limited Time Sale

Limited Time Sale

Until the end

00

00

00

Free shipping on orders over 999 ※)

If you buy it for 999 or more, you can buy it on behalf of the customer. There is no material for the number of hands.

If you buy it for 999 or more, you can buy it on behalf of the customer. There is no material for the number of hands.

There is stock in your local store.

Please note that the sales price and tax displayed may differ between online and in-store. Also, the product may be out of stock in-store.

Coupon giveaway!

| Control number |

New :D718023040 second hand :D718023040 |

Manufacturer | purina dog | release date | 2025-05-15 | List price | $36 | ||

|---|---|---|---|---|---|---|---|---|---|

| prototype | dog food | ||||||||

| category | |||||||||

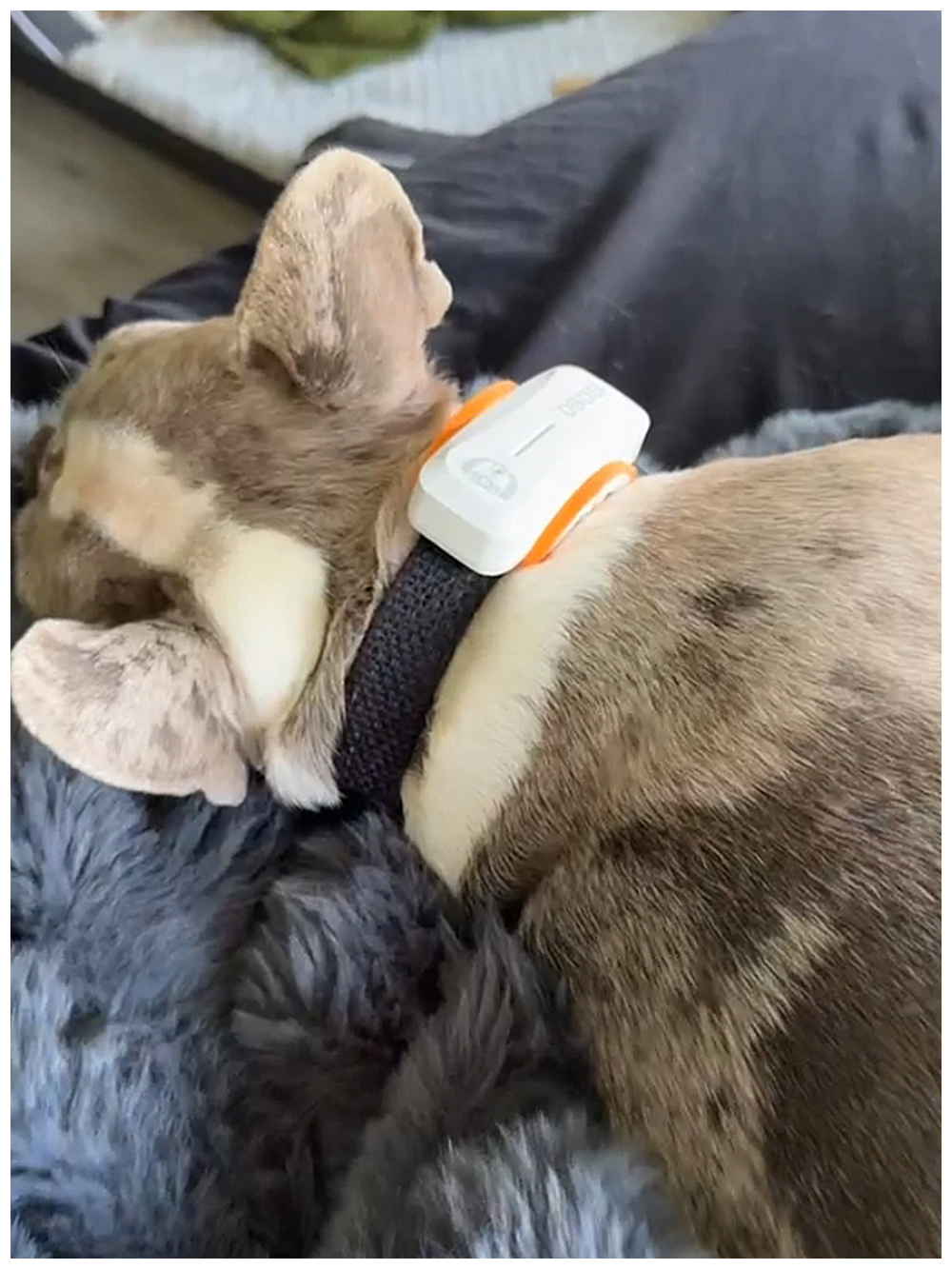

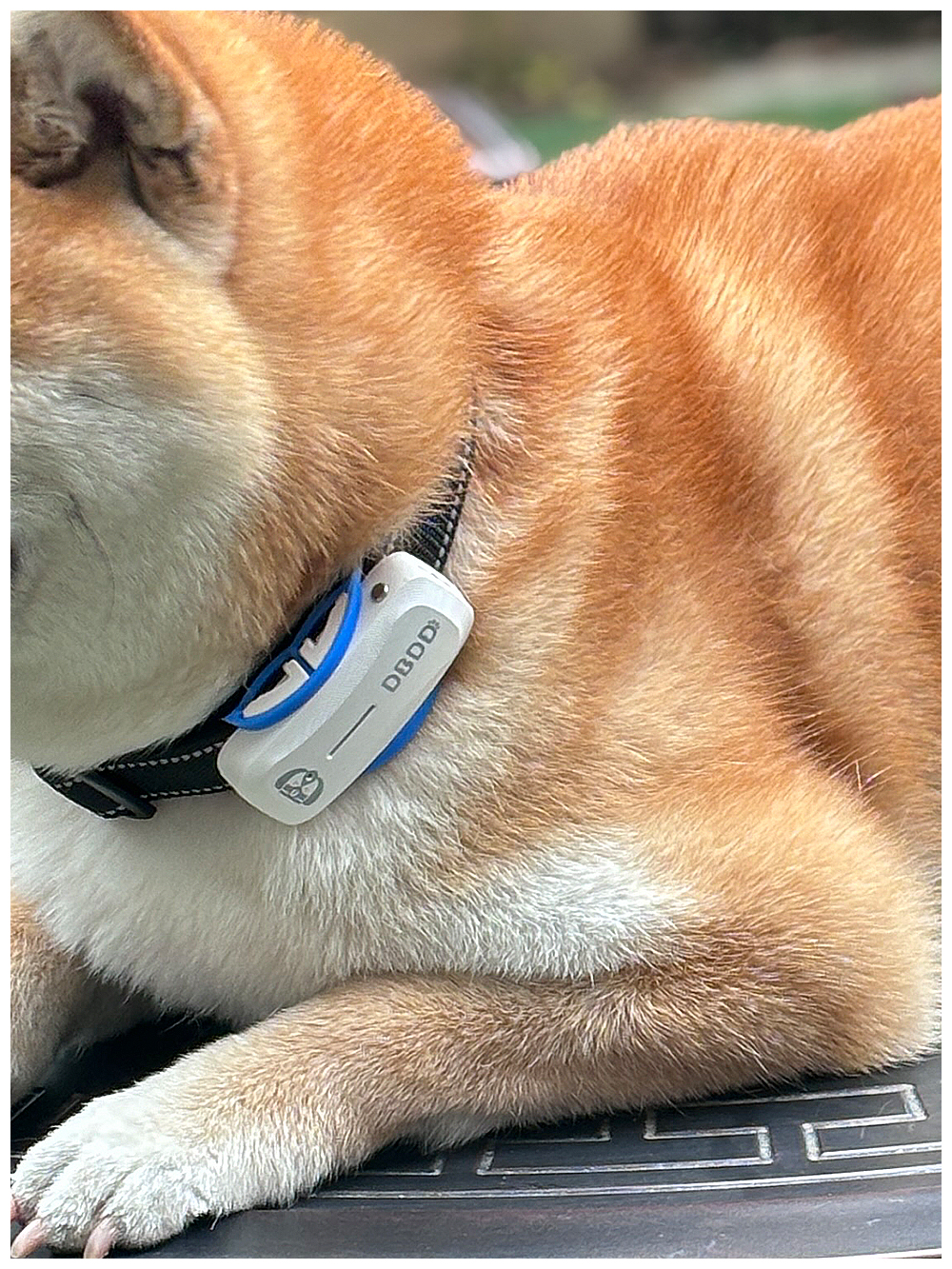

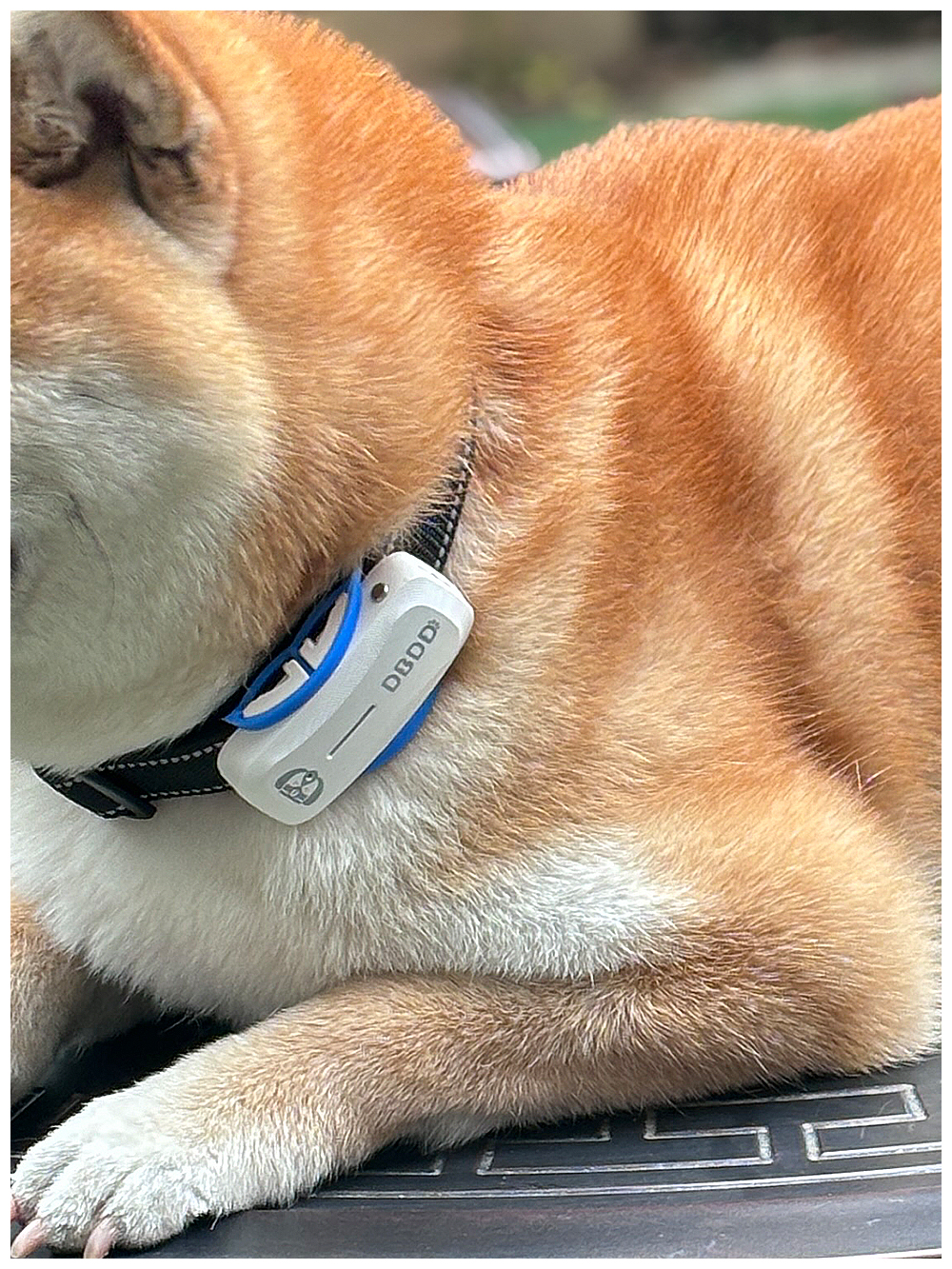

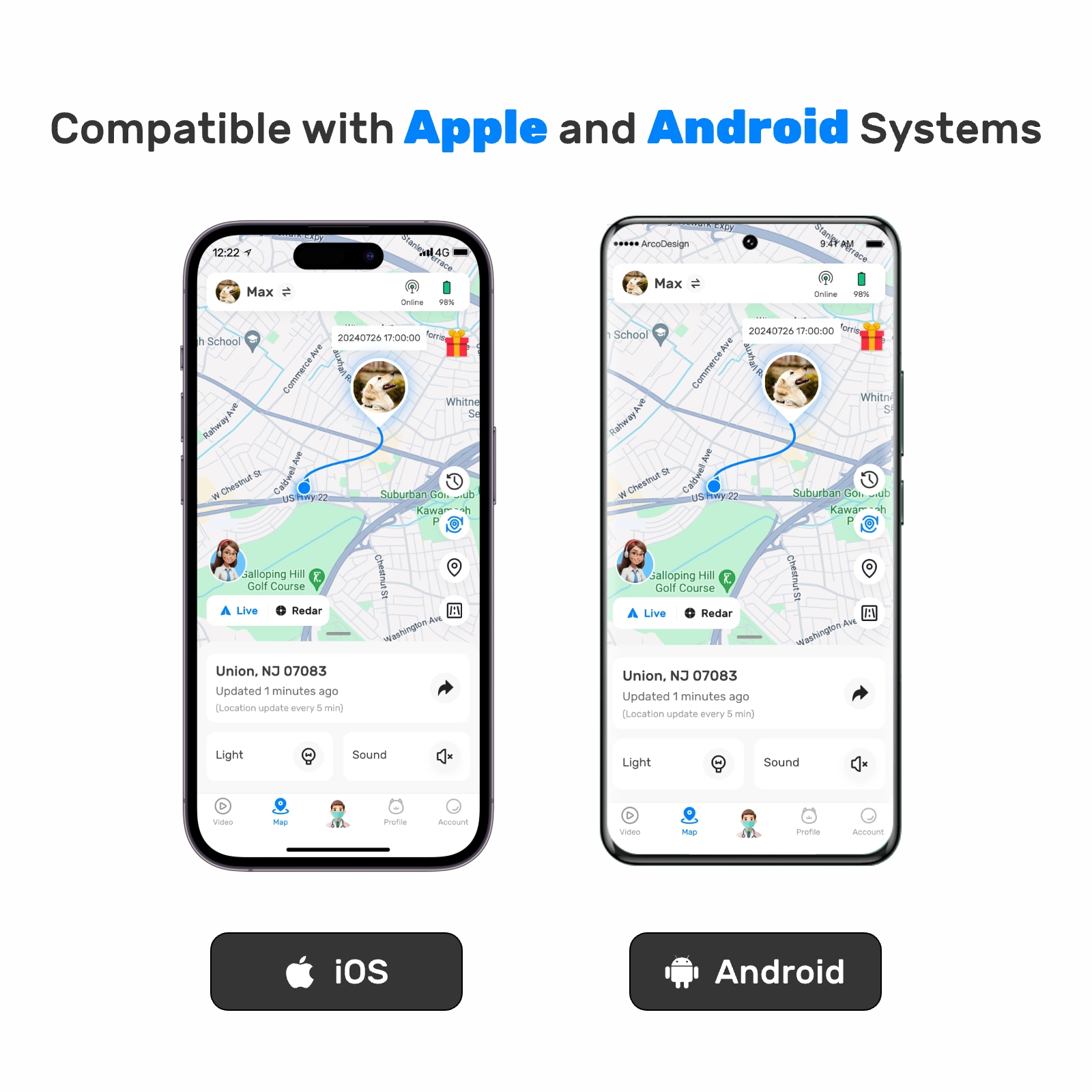

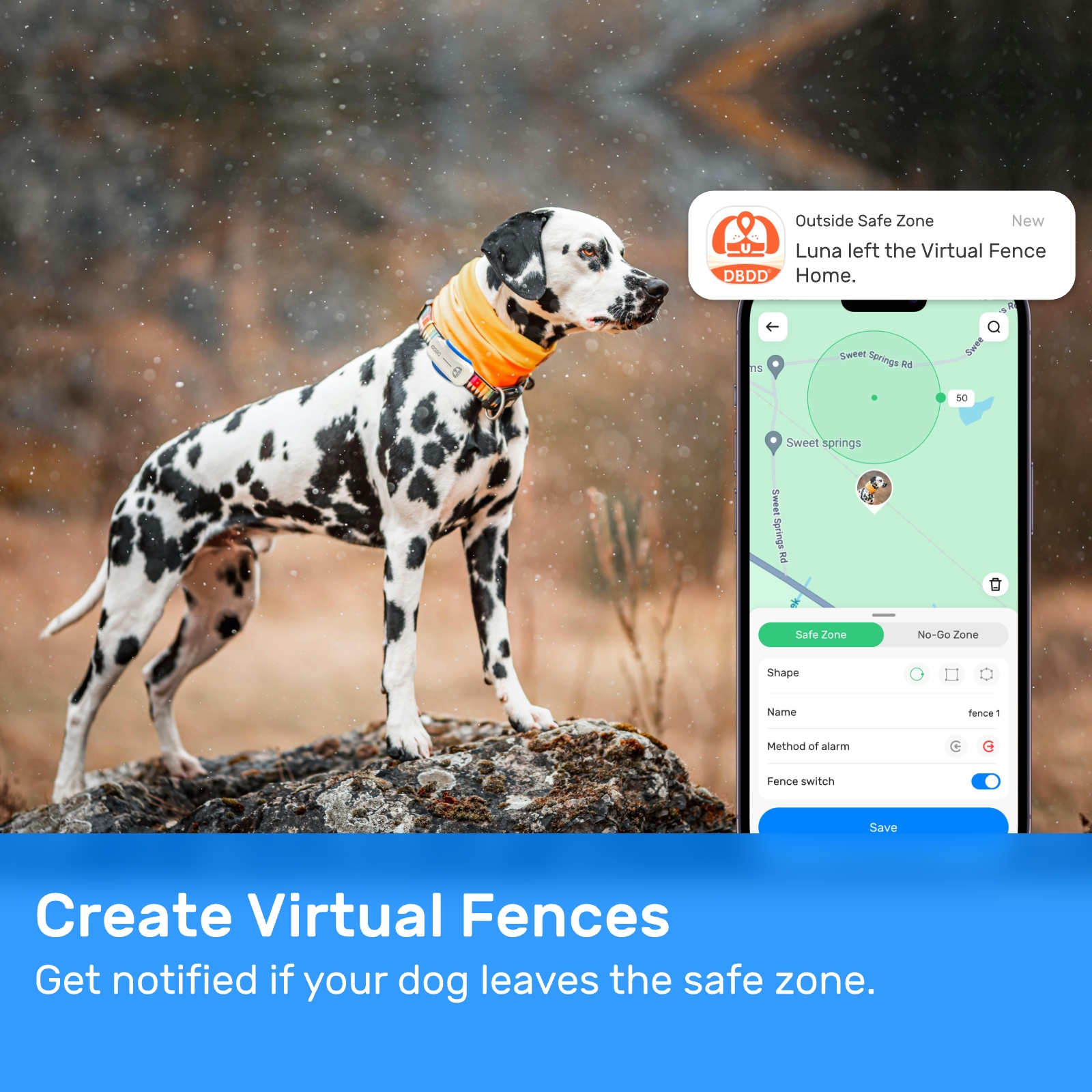

IoT Solutions#Animal Tracking Terminals

gps-dog-tracker-no-subscription

Purina dog food is a well-known and widely used brand in the pet food industry. It has been providing nutritious and wholesome meals for dogs for over 90 years. One of the key factors that contribute to the success of Purina dog food is its commitment to quality and durability. This article will analyze and discuss various studies on the collar material durability of Purina dog food, highlighting the importance of using high-quality ingredients and manufacturing processes to ensure the longevity of their products.

Collar Material Durability: Importance and Significance

Collar material durability is a crucial aspect of pet food production, as it directly impacts the overall quality and safety of the product. Durability refers to the ability of a product to withstand wear and tear over time, maintaining its structural integrity and functionality. In the context of Purina dog food, collar material durability can be understood as the resistance of the food's packaging and components to damage or degradation during storage, transportation, and usage.

The importance of collar material durability in Purina dog food cannot be overstated. It ensures that the product remains fresh, nutritious, and safe for consumption by pets. A durable collar material also helps maintain the product's appearance and prevents any contamination or spoilage, which can lead to health issues for the pet. Moreover, a well-designed and durable collar material can help reduce waste and environmental impact by extending the product's shelf life and minimizing the need for frequent replacements.

Studies on Collar Material Durability of Purina Dog Food

Several studies have been conducted to evaluate the collar material durability of Purina dog food. These studies have focused on various aspects, such as the impact of environmental factors, the quality of raw materials, and the manufacturing processes employed by the company. Some of the key findings from these studies are discussed below.

1. Impact of Environmental Factors

One of the primary factors affecting the collar material durability of Purina dog food is the environmental conditions during storage and transportation. Studies have shown that exposure to extreme temperatures, humidity, and sunlight can significantly impact the quality and durability of the product. To address these concerns, Purina has implemented strict guidelines and protocols for the storage and handling of their dog food products. These measures include maintaining optimal temperature and humidity levels in warehouses, using UV-resistant packaging materials, and ensuring proper sealing and labeling of the products.

2. Quality of Raw Materials

The quality of raw materials used in the production of Purina dog food plays a significant role in determining the collar material durability. High-quality ingredients not only contribute to the nutritional value of the product but also help maintain its structural integrity and resistance to damage. Purina sources its raw materials from reputable suppliers and conducts rigorous quality control tests to ensure that the ingredients meet their strict standards. This commitment to using high-quality raw materials has been a key factor in the company's success in producing durable and long-lasting dog food products.

3. Manufacturing Processes

The manufacturing processes employed by Purina also have a significant impact on the collar material durability of their dog food products. The company has invested heavily in state-of-the-art equipment and technology to ensure that their products are manufactured to the highest standards. Some of the key manufacturing processes that contribute to the durability of Purina dog food include:

- High-temperature extrusion: This process involves subjecting the raw materials to high temperatures and pressures to create the desired texture and shape of the dog food. The high-temperature extrusion process helps to kill any harmful bacteria and pathogens, ensuring the safety and durability of the product.

- Moisture control: Maintaining optimal moisture levels in Purina dog food is crucial for ensuring its durability and preventing spoilage. The company employs advanced moisture control systems to monitor and regulate the moisture content during the manufacturing process, ensuring that the final product remains fresh and stable.

- Packaging and sealing: Purina uses high-quality packaging materials and sealing techniques to protect their dog food products from external factors such as moisture, oxygen, and contaminants. The company also conducts regular tests to ensure the integrity of their packaging and sealing processes, helping to maintain the durability of their products.

4. Shelf Life and Storage

Shelf life is another critical aspect of collar material durability in Purina dog food. Studies have shown that the shelf life of dog food products can be significantly impacted by factors such as temperature, humidity, and packaging materials. Purina has conducted extensive research to determine the optimal storage conditions and shelf life for their dog food products. The company also provides clear guidelines and recommendations to pet owners on how to store their dog food to maintain its quality and durability.

Conclusion

In conclusion, the collar material durability of Purina dog food is a result of the company's commitment to using high-quality raw materials, employing advanced manufacturing processes, and adhering to strict quality control standards. Studies have shown that these factors contribute significantly to the overall durability and longevity of Purina dog food products, ensuring that they remain fresh, nutritious, and safe for pets to consume.

Purina's focus on collar material durability not only benefits pet owners and their pets but also has a positive impact on the

Update Time:2025-05-15 04:45:49

Correction of product information

If you notice any omissions or errors in the product information on this page, please use the correction request form below.

Correction Request Form